**Please note Versatile Tanks DO NOT repair water tanks**

**Please note Versatile Tanks DO NOT repair water tanks**

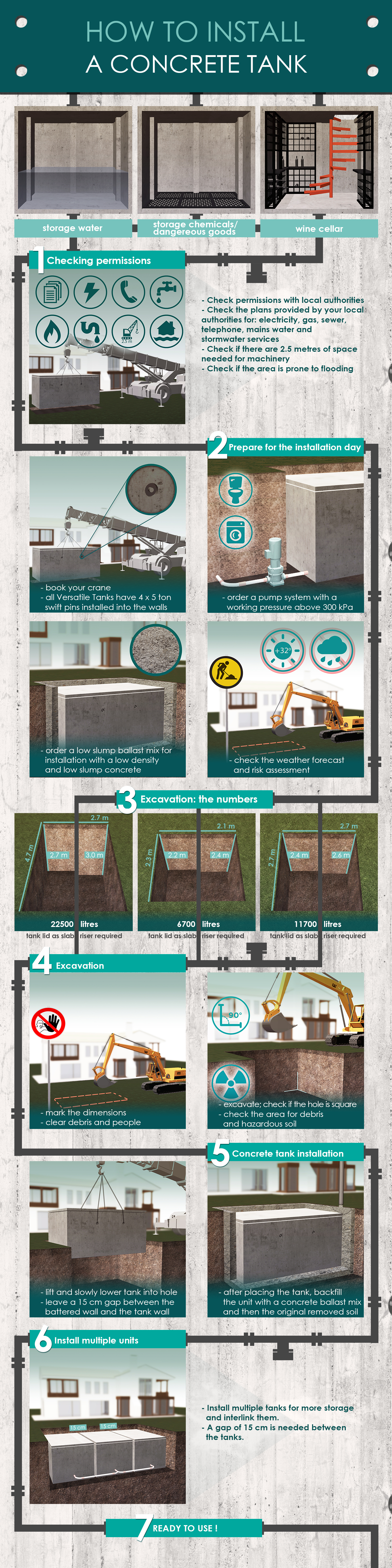

A concrete tank has many uses for a domestic or commercial property: storage of water, storage of chemicals and dangerous goods, or a wine cellar are just some examples. With Versatile Tanks, there’s the extra benefit of the tanks being square and rectangular, rather than the traditional circular tanks that are on the market. Square tanks means you can have multiple concrete tanks installed next to each other, or they can be more easily installed underground. So if you need more storage space for your business or a wine cellar in your home but don’t want to sacrifice a room, then install a concrete tank underground and lay your driveway over the top.

So it makes sense to choose a square tank from Versatile Tanks if you’ve already made the decision to install one. But if you’re now wondering how to install a concrete tank, then the following guide will be all you need to make the process go as smooth as possible.

It isn’t as simple as digging a hole and dropping the tank inside! You’ll need to carefully plan and take the advice from experts. The excavation of the land will need to be made with just as much precision as the installation of the tank. And there are a few things to think about once the tank has been installed or if you decide install multiple tanks.

Consider everything that’s mentioned in this guide and then work out a completion date. If you’re hoping to have a new wine cellar installed for your birthday next month, you might need to readjust your expectations. But once plans have been set and your tank is installed, you’ll have a storage space that’s robust and long-lasting.

First things first

Before you start the physical process of installing a concrete tank underground, you need to plan extremely well. If you choose a reputable tank seller and engineer, they should help you with this and sit down with you to explain the process. So that huge tank that’s going to be part of your home or business doesn’t have to be a huge burden on your mind.

Just make sure you have the following things in order:

Check your permissions to installing this tank

For instance, you may need a permit for installing or using the tank from your local municipal council or they may require a minimum set back distance from buildings and boundary fences. Your local water authority can advise if you need any additional backflow prevention products to be added to mains supplied water.

Your tank and the land it’s going into needs to match

There needs to be adequate access for the machinery that will complete the installation – 2.5 metres is recommended but the excavator and concete suppliers should give you a more accurate measure. The surrounding land also needs to be checked for any electricity gas, sewer, telephone, mains water and stormwater services. Your local authorities for each service can provide plans for these. Check that a downpipe can be suitably diverted to the proposed tank. Finally, if the area where your tank will be installed is prone to flooding or pooling of water or tidal activity, you will need to seek an alternative installation method, which your excavator or concrete supplier can help you with.

Book your suppliers and ensure everything is ready for installation day

A good expert to have involved is a geotechnical specialist, who will foresee any potentially complex site installation issues. Make sure you have a crane booked to unload your tank off the supplier’s truck. It’s a good idea to have the crane operator visit your site beforehand to check for issues too – for example the position of overhead powerline wires.

Cranes must be operated by certified operators and a dogman may be required. Work with your chosen crane operator to plan effectively for the installation. Confirm with them that tanks will be lifted with a certified engineered rated spreader bar to ensure the chains do not damage the lid of the tank. All lifting gear including D shackles must be safe and certified to the relevant standards. All Versatile Tanks, regardless of size, have 4 x 5 ton swift lift pins installed into the walls of the tanks.

You will require a pump system to pump the water from your tank. If the tank water is to be used in toilets, washing machines or high-pressure applications, a pressure pump with a working pressure of above 300kpa is recommended. You should speak with a pump manufacturer for the most suitable pump for your particular application and you may require a licensed electrical contractor.

Also place an order for a stabilised backfill. The low slump ballast mix used for this installation must be a low density (10-15mpa), low slump (around 80) concrete that is easy to manage and not shift the tank about in your excavated cavity.

You will need to have approximately 100mm deep of washed sand or crusher dust available for placement at the base of the excavation hole prior to lowering the tank into the hole.

The final checklist

As with any large outdoor project, the weather plays a large part. If the forecast is rain of a temperature above 32 degrees Celsius, you’ll need to rearrange installation day.

Confirm with your supplier that your tank has been thoroughly inspected prior to leaving the manufacturing plant. And then before it reaches your site, undertake a risk assessment and prepare a safe work method and plan. Safety is of paramount importance, so barricade the site and install safety signs. As well as keeping you and your suppliers free from harm, these measures comply with OH&S/environmental regulations and Codes of Practice.

Installation and Excavation

When you’ve prepped your site for installation, contacted your suppliers and any other companies who need to know your plans, and ordered what you need, the installation of your tank can commence.

Excavation: The numbers

You’ll need to excavate the cavity at least 200mm wider than the external dimension of your tank. The following size guides are for the excavation area for your new tank:

- 22500litre

If using tank lid as a slab: 2.7m deep (if placing slab on tank lid calculate your slab thickness on top of tank) x 2.7m wide x 4.7m long.

If burying tank to maximum depth and riser required (300mm high): 3.0 m deep x 2.7m wide x 4.7m long. This includes 100mm sand bed.

- 6700 litre

If using lid as a slab: 2.2m deep (if placing slab on tank lid calculate your slab thickness on top of tank) x 2.1m wide x 2.3m wide.

If burying to max depth and 200mm riser required: 2.4m deep x 2.1m wide x 2.3m wide. This includes 100mm sand bed.

- 11700 litre

If using lid as a slab: 2.4m deep (if placing slab on tank lid calculate your slab thickness on top of tank) x 2.7m wide x 2.7m long.

It’s important not to over-excavate – only dig the required cut out and ideally a clean cut hole is best for installation of tank.

Before, during and after excavation

Once you have your excavation dimensions, you can mark the area on your site. You’ll also need to clear all debris and obstructions from around the site and make sure the machinery can access it. Your marked dimensions should take into account where the riser will be positioned. This is used for access and connection to services, so it needs to be in the most convenient location.

Just before excavating, have a final check that there isn’t going to be a downpour of rain and that there aren’t any unauthorised persons near the area. Angle the batter according to the soil conditions to ensure stability and commence excavation.

Once complete, remove the soil to a safe distance away from the hole. At this point, have a good look to see that the sides of the hole are 90 degrees to each other. You’ll come up against many problems trying to install your Versatile Tank into a hole that isn’t square! Also check that there is a level base and that it is smooth. Protruding objects like stone or rock could damage the tank.

Finally, check for any evidence of soil contamination that may be hazardous and/or adversely affect the tank installation. If all is clear, then the area is ready for your concrete tank.

Your concrete tank installation

If you’ve prepared well, your suppliers will have all of the correct equipment and be in tune with each other to safely get your concrete tank into the excavated hole.

Start by placing a 100mm sand bed for your concrete tank to sit on. Then make sure the crane operator is ready. The crane must use 4×5 ton certified swift lift lugs using the pins moulded into the tank with only safe, certified lifting equipment and a spreader bar to avoid chains damaging the tank lid. Place metal bars in the walks of the unit if your engineer has hydro lift issues.

Lift and slowly lower the tank into hole, centring it with a minimum 150mm gap between the battered wall and the tank wall. Once the tank is in hole, backfill the unit with a concrete ballast mix – just enough to cover the external anchor bars.

You will backfill using the shute from the concrete truck. Aim it directly into the hole slowly and work the mix around the base of the tank ensuring it fills all excavation voids. This assists in preventing surface water from working its way around tank as well as preventing uplift of the tank.

Backfill the remainder of the cavity with the soil you initially removed and do your final checks around the area before your suppliers leave. Ensure your external stormwater and drainage is directed away from your tank.

Multiple tank installation

There are a few extra points to note if you’re installing multiple tanks. One of the advantages of choosing a square Versatile Tank is that they can fit together as a modular system, joining them together to provide additional storage capacity.

If you’ve planned for your tanks to be for water storage, two or more tanks may be linked at installation by installing a tank boss. Sleeves placed into the tank or a plumber can create a neat hole at the base of the tanks on site to interlink them.

When installing multiple tanks, you must note that a gap of approximately 150mm between the tanks is required. This enables you to get the swift lift clutches off the tank. Also, multiple tanks must always be installed at the same level i.e. the base must be level under both tanks.

Making the decision to install multiple tanks is best done when ordering, as your supplier can make alterations and place suitable fittings in the tank to suit your needs and the site requirements

Your new concrete tank: ready for use

So your tank is has now been fully and safely installed. Let the structure settle in position before you start using it, particularly if you’re going to add features inside. For instance with wine cellars, Versatile Tanks also provides stair and racking options.

Over the following days from installation, you’ll notice if there are any issues. But the seamless mould and strong concrete mix that Versatile Tanks are made with should eradicate this potential issue. This is just one of the advantage of buying a square tank over a circular – there are no joins for water to leak into or cracks to form. The tank will be strong, safe and long-lasting.

Above ground, the land above the tank will also settle down and you can lay a driveway over the top or use this space for something useful – something you wouldn’t be able to do if you decided to go for an above-the-ground tank. Your tank will be securely underground, providing you with lots of storage space that isn’t visible when visiting your home or business.

You will need to have approximately 100mm deep of washed sand or crusher dust available for placement at the base of the excavation hole prior to lowering the tank into the hole.

Lift and slowly lower the tank into hole, centring it with a minimum 150mm gap between the battered wall and the tank wall.

Once the tank is in hole, backfill the unit with a concrete ballast mix and then the original removed soil.